Energy

Why is it Imperative to Reduce Energy

As greenhouse gases lead to rising global temperatures and increased CO2 levels in the atmosphere, there is an urgent need for us to find more efficient ways to manage resources. Retreading of tyres saves significant quantities of energy, as it takes approximately 30% less energy to produce a retread tire.

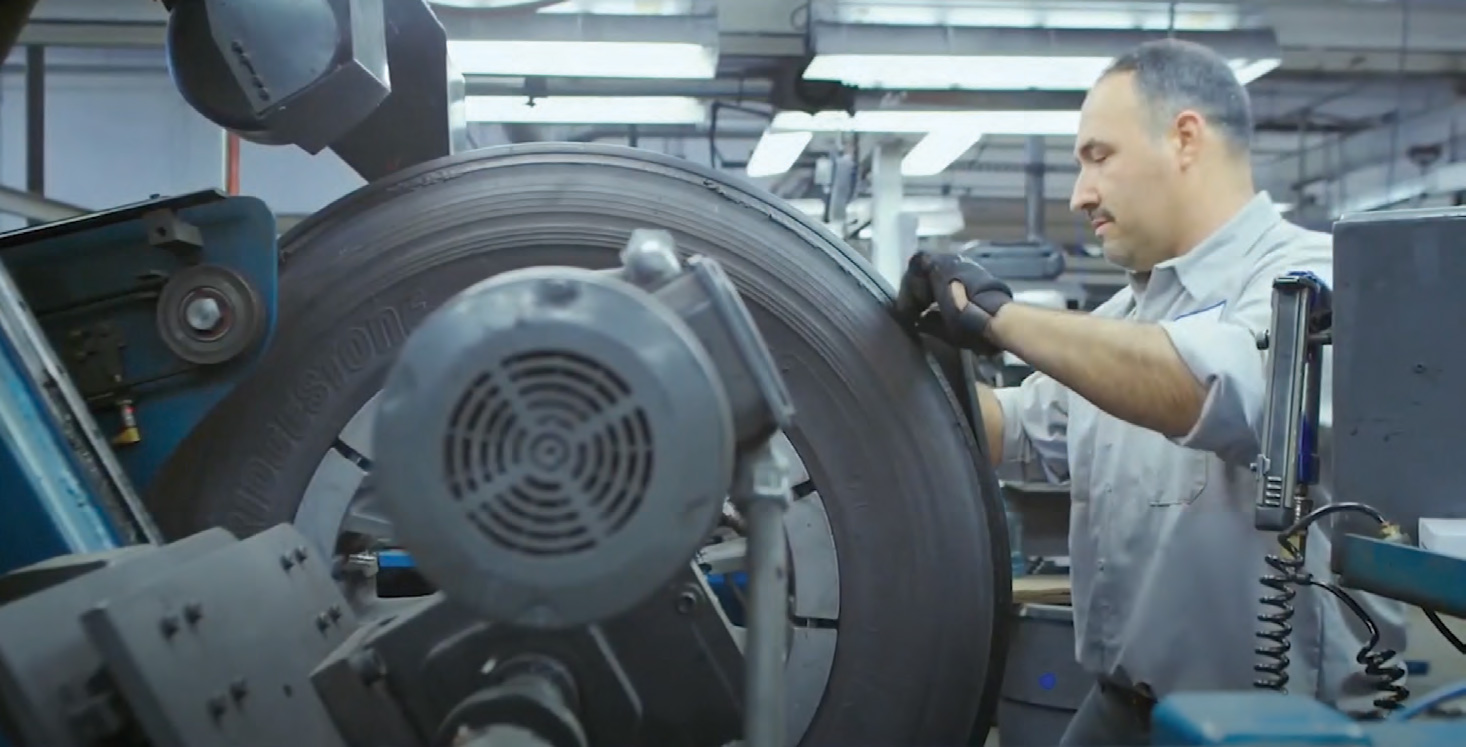

Leading the Way in Re-treading Tires

With almost double the market share of the nearest competitors – and more than double the number of plants – there’s no bigger name in energy-saving tire retreads than Bandag.

Less Oil Required in Retreading

In the manufacturing process, a quality retread tyre requires a fraction of the oil as compared to a new tire. With the projection of oil depletion to occur within 50 years, we feel this switch is critical.

Ecology

Vital to Reduce Dependence on Non-Renewables

Individual and collective actions affect the environment. At Bandag, we actively search for solutions to overcome land and resource degradation, depletion, and scarcity. Our retreading of tires is a big step towards being a more environmentally responsible society.

Conserving Resources, Reducing Tire Wastage

Bandag helps fleets reduce their environmental footprint, by managing the future scarcity of raw materials and ensuring efficient use of key resources. Up to 75% of our tire material is recycled and reused through a sustainable production process. In 2021 alone, the use of Bandag retreads saved over 94 million gallons of oil, 186 million pounds of tire waste – enough energy to power 168 million homes for a day.*

Respecting Finite Land, Water and Natural Resources

Because natural resource extraction continues to take a heavy toll on Earth, we are constantly on the lookout for renewable energy sources, to lower our dependence on non-renewable ones. For example, we have had experimental trials on recycled materials to reduce our dependence on other raw materials, including synthetic rubber. All such efforts are aligned to our Long Term Environmental Vision 2050 of valuing natural resources and using more sustainable materials.

Efficiency

The Importance of Optimised Efficiency

From conceptualisation to roll-out of our tires, Bandag pays close attention to creating more efficient and superior retreads. This is so that resource use can be optimised and wastage prevented. Our overriding goals are to deploy scarce resources efficiently, extend the tire lifespan and deliver a reliable final product.

Unique Tread Design For Improved Wear Life

Through constant innovation, Bandag produces advanced and efficient tires with an eye on cost savings for fleets. Also, improving wear life translates to less frequent replacements, thereby spiking business productivity.

Innovation for Longer-Lasting Products

Research and development into Bandag’s product line up helps us continuously streamline production, with an aim to produce longer lasting products to fight irregular wear. Ultimately, we want to deliver more kilometres with less rubber.

Economy

The Importance of Achieving Economy

Developing cost-effective products and creating value through lower price points ultimately results in savings for fleet operators and end-users. Retreading lowers pricing of tires, prolongs usage and delays replacement, to bring greater economy to users.

Co-creation of Value through Cost Efficiency

Retreading delivers tires at a lower cost compared to new tires – without any compromise on quality and safety. In fact, retreaded tires can even outlast some brand new tires.